While many robotics companies are building human-sized robots or working to automate entire factories, MicroFactory is trying to think big by building small. This San Francisco-based company has built a general-purpose, tabletop manufacturing kit that is about the size of a large dog crate. This compact factory includes two robotic arms and can be trained by human demonstration as well as through AI.

Igor Kulakov, the co-founder and CEO of MicroFactory, explained the company’s philosophy. He stated that general purpose robots do not need to be humanoid. By designing robots from scratch without a human shape, the process can be made much simpler and easier, both in hardware and on the AI side.

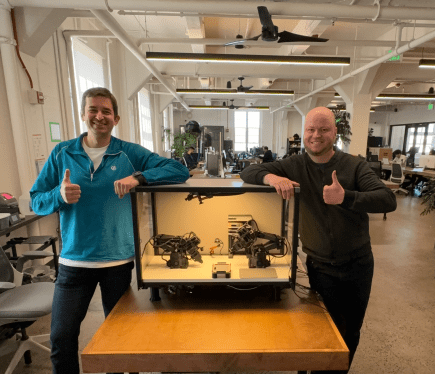

Rather than selling individual robotic arms, MicroFactory’s system comes as an enclosed but transparent workstation. This allows users to watch the manufacturing process in real time. The compact factory-in-a-box is designed for precision tasks like circuit board assembly, component soldering, and cable routing. Users can train the robots by physically guiding the arms through complex motions. This hands-on approach works faster than traditional AI programming for intricate manufacturing sequences.

Kulakov noted that this training usually takes a couple of hours, and the robot better understands its task. He compared it to training new employees, which can take a week or more. Manufacturing companies already have the time and resources to spend on training, making it easier to train a model this way.

Kulakov’s experience with traditional manufacturing helped spark the idea for MicroFactory. He and his co-founder, Viktor Petrenko, used to run a manufacturing business called bitLighter that made portable lighting equipment for photographers. Kulakov found it difficult to train new employees on the correct manufacturing process. When advancements in AI made it possible to automate this type of work, they decided to jump on the opportunity.

Kulakov and Petrenko launched MicroFactory in 2024. It took them about five months to build their prototype. The company now has hundreds of preorders from customers looking to use the machines for various applications, including assembling electronics and even processing snails to be shipped to France for escargot.

MicroFactory just raised a $1.5 million pre-seed funding round. The round included investors like executives from the AI company Hugging Face and investor-entrepreneur Naval Ravikant. This round values the young startup at a $30 million post-money valuation.

Kulakov said the company plans to use the funding to build and ship out its units. It is currently converting its prototype into a commercial product and hopes to begin shipping in about two months. The company also plans to make new hires and continue improving its technology, including the AI models running the system.

The company has set ambitious growth goals related to building hardware, aiming to increase production tenfold each year. In the first year, the goal is to produce one thousand robots, which is about three per day. The company believes it has the capability to achieve this and then plans to make more and more units.