For decades, engineers designing space structures have been constrained by the rocket fairing. Only hardware that can be folded up to fit inside can go to orbit. This makes in-space assembly time intensive and expensive. The International Space Station, the largest single object humanity has built in space, was assembled over dozens of launches and cost over one hundred billion dollars. Furthermore, there is no way to modify or alter the structure once it has been assembled.

Rendezvous Robotics wants to change that. According to co-founder and President Joe Landon, mission designers are constrained by two things. They must build something that can fit or fold into a rocket and also constrain themselves by the satellite bus they will use. He notes that missions increasingly need more scale and size, such as larger antennas, higher power, and the larger radiators required to manage that power.

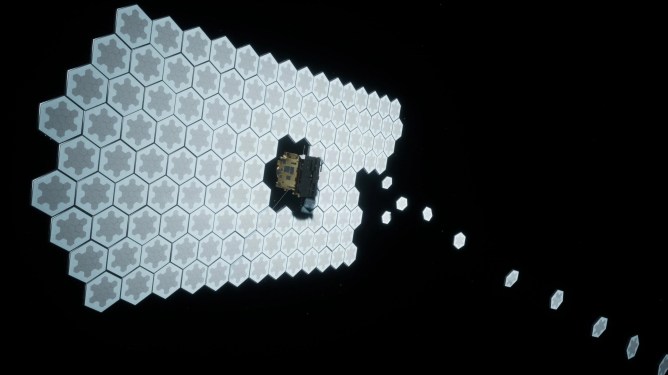

Instead of relying on astronauts and robotic arms, Rendezvous is betting on autonomous swarm assembly and electromagnetism. The company is commercializing a technology called tesserae. These are flat-packed modular tiles that can launch in dense stacks and magnetically latch together to form structures in orbit. With a simple software command, the tiles are designed to unlatch and rearrange themselves when the mission needs to change.

The tiles find each other, communicate, and arrange themselves using magnetic docking before latching together. This means if you want to change an arrangement, replace a component, or perform an upgrade, you can just send a command. The tiles can unlatch, move to a new location, go into storage, or come out of storage to create a new configuration.

The current tiles are around the size of a dinner plate and roughly an inch thick, though the team envisions scaling them to the diameter of a rocket fairing. Each tile has its own processor, a variety of sensors, and a battery. The CEO and co-founder, Phil Frank, describes these as pretty simple devices designed for mass manufacturing at low cost.

The technology was invented by Ariel Ekblaw during her time at MIT and was incubated at the Aurelia Institute, the nonprofit organization she founded. She teamed up with Frank, a telecom veteran, and Landon, a longtime space executive, to spin the tech out of Aurelia and take it to the commercial marketplace. The company was formalized around Thanksgiving in 2024.

Landon, who started his career as an engineer in Boeing’s commercial satellites business and later led research and development at Lockheed Martin Space, said the company is headquartered just outside of Denver.

Rendezvous closed a three million dollar pre-seed funding round led by Aurelia Foundy and 8090 Industries, with participation from ATX Venture Partners, Mana Ventures, and angel investors. The funding will be used to hire more employees and help move the technology from a demonstration to a full-scale product in orbit.

The company is first targeting missions where physical scale and size drive performance, such as those demanding large solar arrays or large antenna apertures. On the commercial side, the focus is on communications missions that need large antennas to communicate with small antennas on the ground, like those in phones or cars. For national security, the focus is on remote sensing that benefits from very sensitive detection systems.

Tile prototypes have already flown on Blue Origin’s New Shepard and on two missions aboard the International Space Station. The ISS demonstrations proved out the autonomous docking, self-correction, and reconfiguration capabilities. Looking ahead, the company is aiming to conduct another demo on the ISS in early 2026, followed by a mission outside the station in late 2026 or early 2027. That will be followed by a real mission that shows mission utility, such as building an antenna aperture in space.

As Landon explains, they are not building a specific thing. They are providing a new way to build. It is about how you build, not what you build.